Streamfeeder V-710DM Replace-a-Station Inserter Feeder (9x12)

Product ID: 16342

Year: New

Make: Streamfeeder

Model: V-710DM Replace-a-Station Inserter Feeder (9x12)

Click here to contact us about this product »

The Streamfeeder V-710DM Replace-a-Station Inserter Feeder (9x12) provides the flexibility of automating “jumbo” format gripper arm inserters and inkjet/tabber bases. The V-710DM allows for quick and easy installation onto most major brands of vacuum/non-vacuum bases and gripper arm inserters. Increases the throughput and reliability of addressing bases.

Overview:

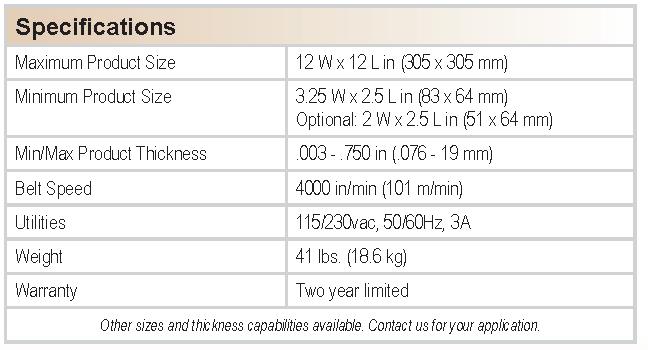

The V-710DM Replace-a-Station Inserter Feeder combines flexible performance with superior feeding capabilities to precisely separate, isolate, and present many types of product types and sizes to the gripper jaw of “Large Format / Jumbo” swing arm inserters. Job setups and changeovers are easily and quickly accomplished via tool-less adjust features. A large capacity hopper is designed to be loaded from the front or rear of the machine maximizing operator efficiency. The clutch-free motor provides long, dependable performance and the feeder is backed by a two-year limited warranty. The V-710DM can also be used to feed products continuously to inkjet and tabber bases and comes standard with a dry contact interface that can be wired to bases for synchronized start/stop control.

Applications:

- Swing-arm Inserters

- Inkjet Bases

- Tabbers

- Labelers

Products:

- Sheet Paper

- C-Folds

- Z-Folds

- Manuals

- Business Cards

- Payment Booklets

- Cardstock

- Envelopes Plastic Cards

- Post Cards

- Brochures

- And more!

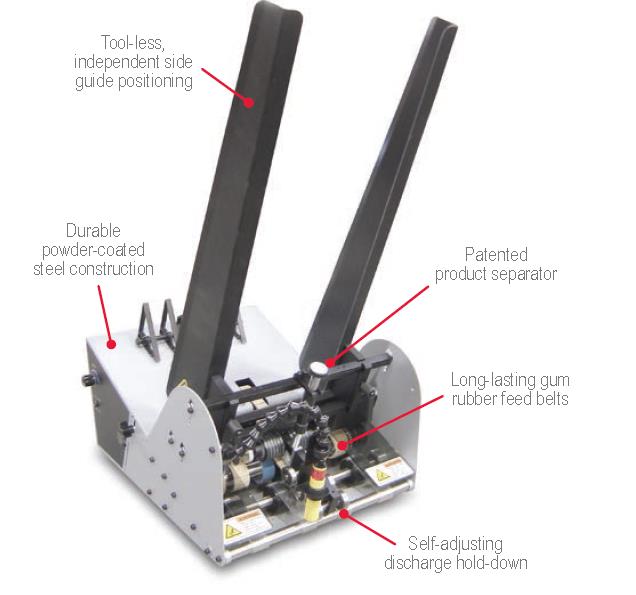

Features

- Long lasting natural gum rubber feed belts

- Independent side guide positioning

- Self-adjusting discharge hold down

- Patented product separator

- High-performance photo sensor with tool-less adjust

- Variable speed control

- Adjustable angle rear feed belts

- Suction cup mounting to the rear inserter table and shuttle plates

- Material control springs to keep products in position at the jaw

- Small product insert plate

- Two wire start/stop interface cable for integration to inkjet and tabber bases